Insertion Equipment

Ultrafab offers insertion equipment on loan for qualifying customers at no additional charge, along with on-site training and technical assistance. Our patented designs facilitate ease in pile weatherstrip insertion for fabricators and extruders.

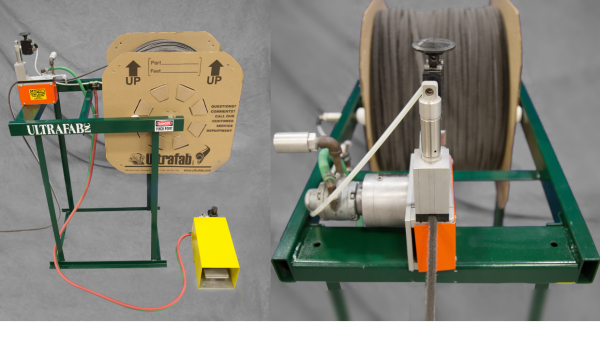

Metered Insertion Machine

Designed for insertion of weatherstripping at point of fabrication.

Designed for insertion of weatherstripping at point of fabrication.

- Automatically inserts Ultrafab’s standard or patented ULTRA LOC® weatherseals into aluminum or vinyl sash and frame lineals

- Problem-free filling at the rate of up to 3,000 feet/hour (6 feet/second)

- Operates with electrical power and compressed air

- Up to 70% increased productivity versus hand pulling insertion

- Durable mechanical design assures safe, reliable operation

- Ultrafab’s patented ULTRA LOC® base eliminates gluing or staking of the weatherseal

- Customizable for all sash and frame shapes

- Tail feet option allows for alignment of weatherseal into extrusion.

- Pneumatic brake stops the reel from over-running after each insertion

- Programable with your desired length and automatically fills the lineal.

- Automatically cuts weatherseal to a tolerance of one inch

- Built-in safety features include tamper-proof fasteners and full guarding

- On-site Training and technical assistance are included with every machine.

- Equipment is available on loan to qualifying customers.

| Metered Insertion Machine Specifications | |

|---|---|

| Speed: | 6 feet per second |

| Profiles: | All configurations |

| Pile Heights: | .140″ to .500″ (3.6 to 12.7mm) |

| Backing Widths: | .187˝ (4.75mm), .200˝ (5.08mm), .210˝ (5.33mm), .229˝(5.82mm),.250˝ (6.35mm), .255˝ (6.48mm), .270˝ (6.86mm), .310˝ (7.87mm) |

| Electrical: | 115 VAC 60Hz |

| Air Pressure: | 80 psi clean dry air |

| Dimensions: | 54″ H x 26″ W x 36″ L |

| Weight: | >106 lbs |

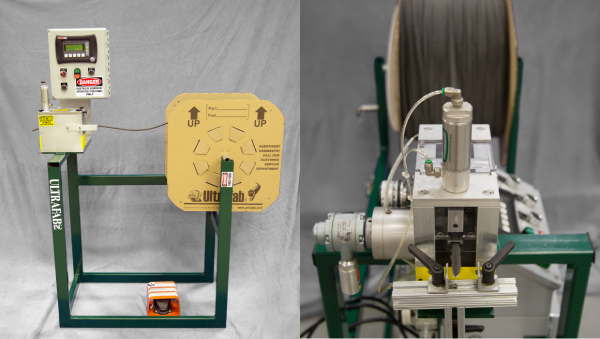

Non-Metered Insertion Machine

Designed for insertion of weatherstripping at point of fabrication.

Designed for insertion of weatherstripping at point of fabrication.

- Automatically inserts Ultrafab’s standard or patented ULTRA LOC® weatherseals into aluminum or vinyl sash and frame lineals

- Problem-free filling at the rate of up to 3,000 feet/hour (6 ft. per second)

- Operates with compressed air.

- Up to 70% increased productivity versus hand pulling insertion

- Durable mechanical design assures safe, reliable operation

- Ultrafab’s patented ULTRA LOC® base eliminates gluing or staking of the weatherseal

- Customizable for all sash and frame shapes

- Pneumatic brake stops the reel from over-running after each insertion

- Pneumatically cuts weatherseal

- Built-in safety features include tamper-proof fasteners and full guarding

- On-site training and technical assistance are included with every machine.

- Equipment is available on loan to qualifying customers.

- Table top mount available to conserve floor space

| Non-Metered Insertion Machine Specifications | |

|---|---|

| Speed: | 6 feet per second |

| Profiles: | All configurations |

| Pile Heights: | .140″ to .500″ (3.6 to 12.7mm) |

| Backing Widths: | .187˝ (4.75mm),.200˝ (5.08mm), .210˝ (5.33mm), .229˝ (5.82mm),.250˝ (6.35mm), .255˝ (6.48mm),.270˝ (6.86mm), .310˝ (7.87mm) |

| Air Pressure: | 80 psi clean dry air |

| Dimensions: | 31″ H x 17″ W x 24″ L |

| Weight: | 24 lbs |

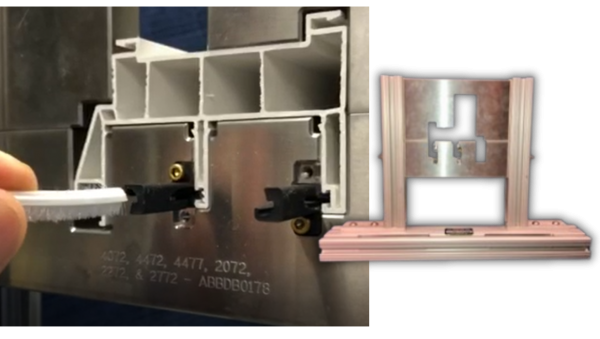

OPIS – Pile Insertion System

Labor saving automation equipment automatically fills extruded lineals. Inserts Ultrafab’s standard, ULTRA FILL®, and ULTRA PRO® weatherseal backings into vinyl sash and frame lineals during the extrusion process. This value add service will not impede the extrusion process and runs on high speed lines. All machines are customized to fit specific profiles.

Labor saving automation equipment automatically fills extruded lineals. Inserts Ultrafab’s standard, ULTRA FILL®, and ULTRA PRO® weatherseal backings into vinyl sash and frame lineals during the extrusion process. This value add service will not impede the extrusion process and runs on high speed lines. All machines are customized to fit specific profiles.