AngleOn™ Durability

Predicting AngleOn™ Longevity through Comparative Wear Analysis

How Durable Is AngleOn™?

Accurately measuring a product’s lifespan is key to both improving our designs and standing out in the market. To make it meaningful, we focused on two types of testing:

- Real-use wear data to understand how AngleOn™ performs in the field

- Accelerated lab testing to simulate long-term stress in a shorter time

By combining these methods, we created a reliable, data-backed view of how long AngleOn™ lasts.

Test

Real-Use Testing (UF-24-236)

- Setup: 100 objects, each weighing 0.25 lb, were tested in a real production environment.

- Object Specs:

- Contact Area: 1.323 in²

- Coefficient of Friction (CoF): 0.09 (Material: zinc-plated steel 1/2″- 13 hex nuts)

- Duration: Continuous testing over 400 hours

- Results:

- Brush height decreased by 0.020 inches

- Material loss rate: 0.0000498 inches/hour

Accelerated Wear Testing (UF-25-105)

- Test Environment: Controlled abrasion apparatus

- Test Objects:

- Loading & Motion: Comparable to real-use conditions

- Intensification: Conditions increased to speed up wear

- Duration: Shortened time to induce measurable wear

- Materials Tested:

- AngleOn™

- Competitor product

- Results:

- Material Loss Rates: Measured as a function of belt speed (in/sec)

What the Data Shows

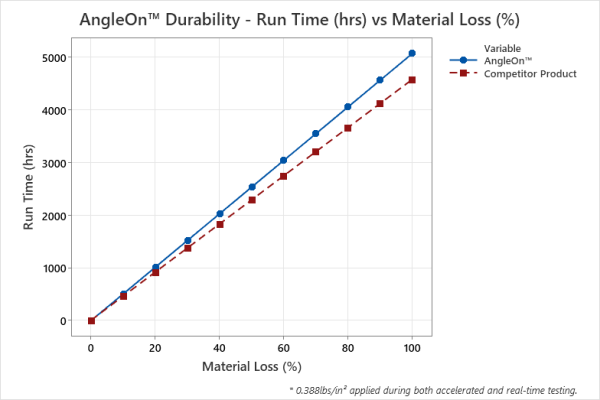

The graph below charts run time (in hours) against material loss (in 10% increments), comparing the performance of AngleOn™ with a leading competitor.

The Results

AngleOn™ clearly outperformed the competing product. It showed superior durability and wear resistance under identical test conditions—proving it’s built not just to perform, but to last.

This blended testing approach doesn’t just support product improvements—it ensures our performance claims are backed by real numbers you can trust.