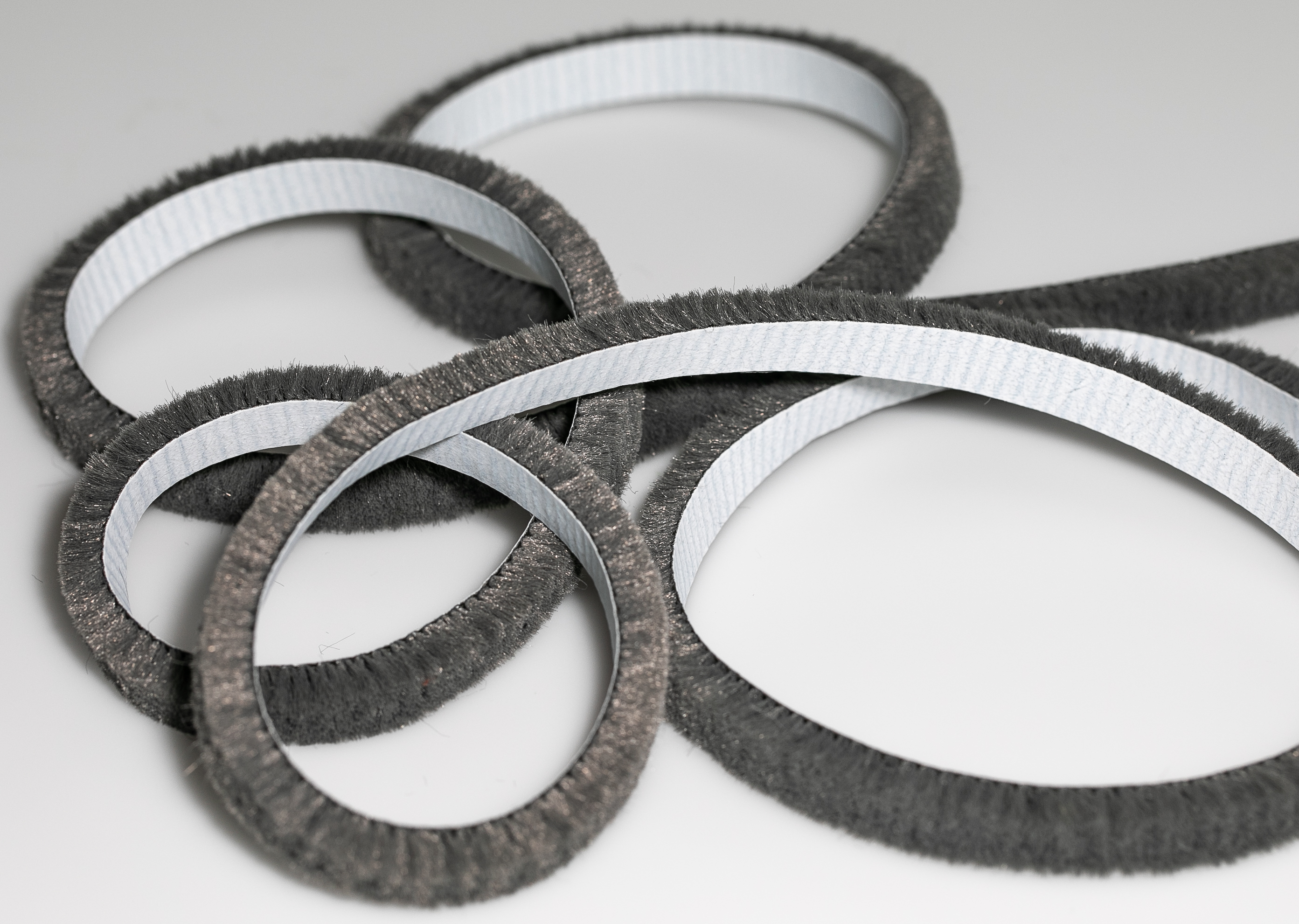

ULTRA BEND®

Ultrafab Product Categories

Looking for something else? Need something you don't see? Ultrafab offers a wide range of products beyond those shown here. Contact us for more information.

Flexible Adhesive-Backed Dust Plug

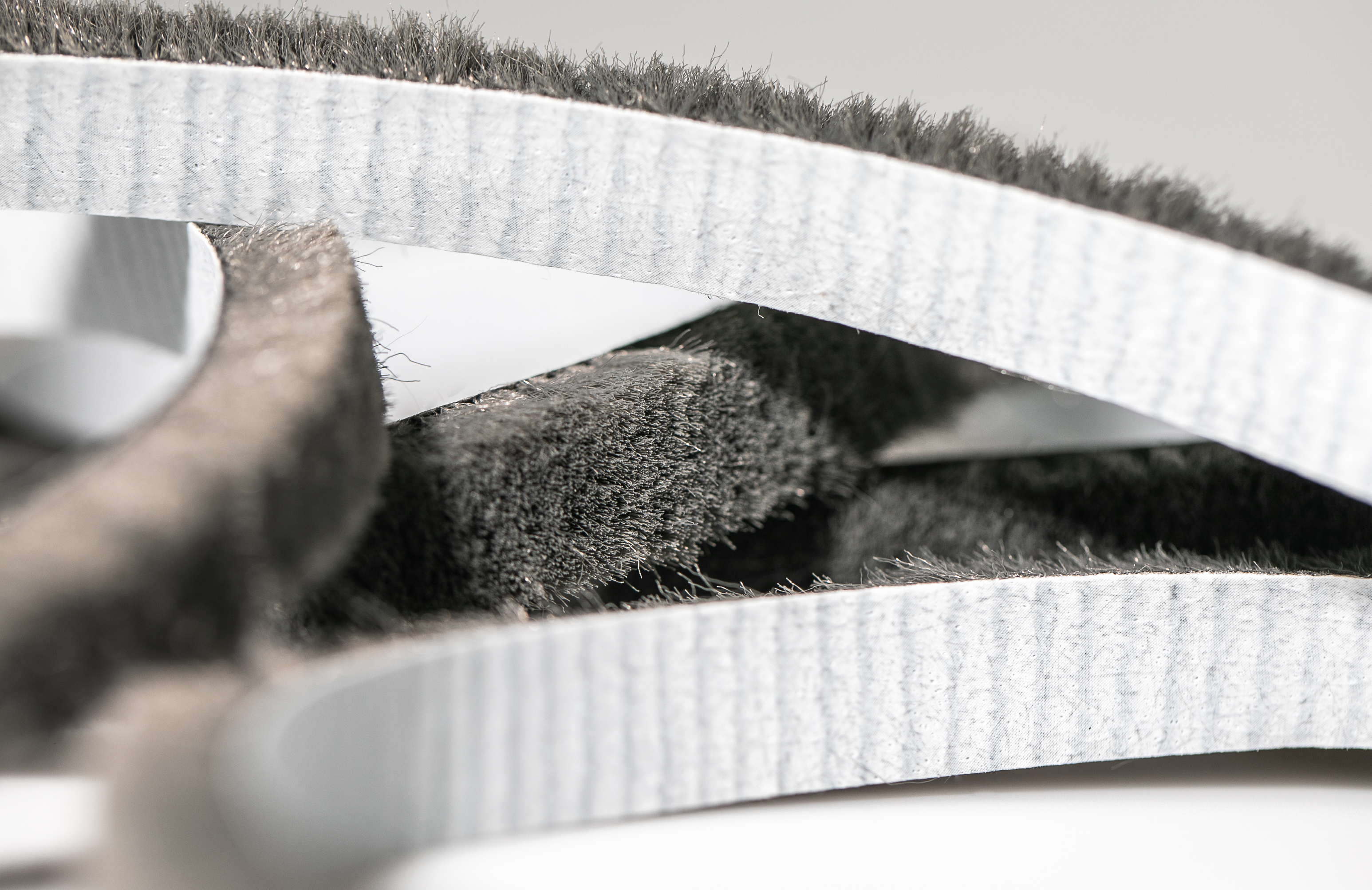

Ultrafab is proud to introduce our new flexible adhesive-backed dust plug. The Ultrafab ULTRA BEND® offers OEMs and engineers a competitive advantage on products that require specific sealing solutions. The flexible-based material allows the sealing product to fit firmly and permanently over uneven surface areas, thus ensuring proper mounting. The flex-back product also features an extremely dense, tight, close fiber configuration that allows for a non-oriented design. This reduces labor by allowing the dust plug to be applied in any direction. The ULTRA BEND® will be readily available in various linear lengths or cut into plugs.

Description

Sealing Applications

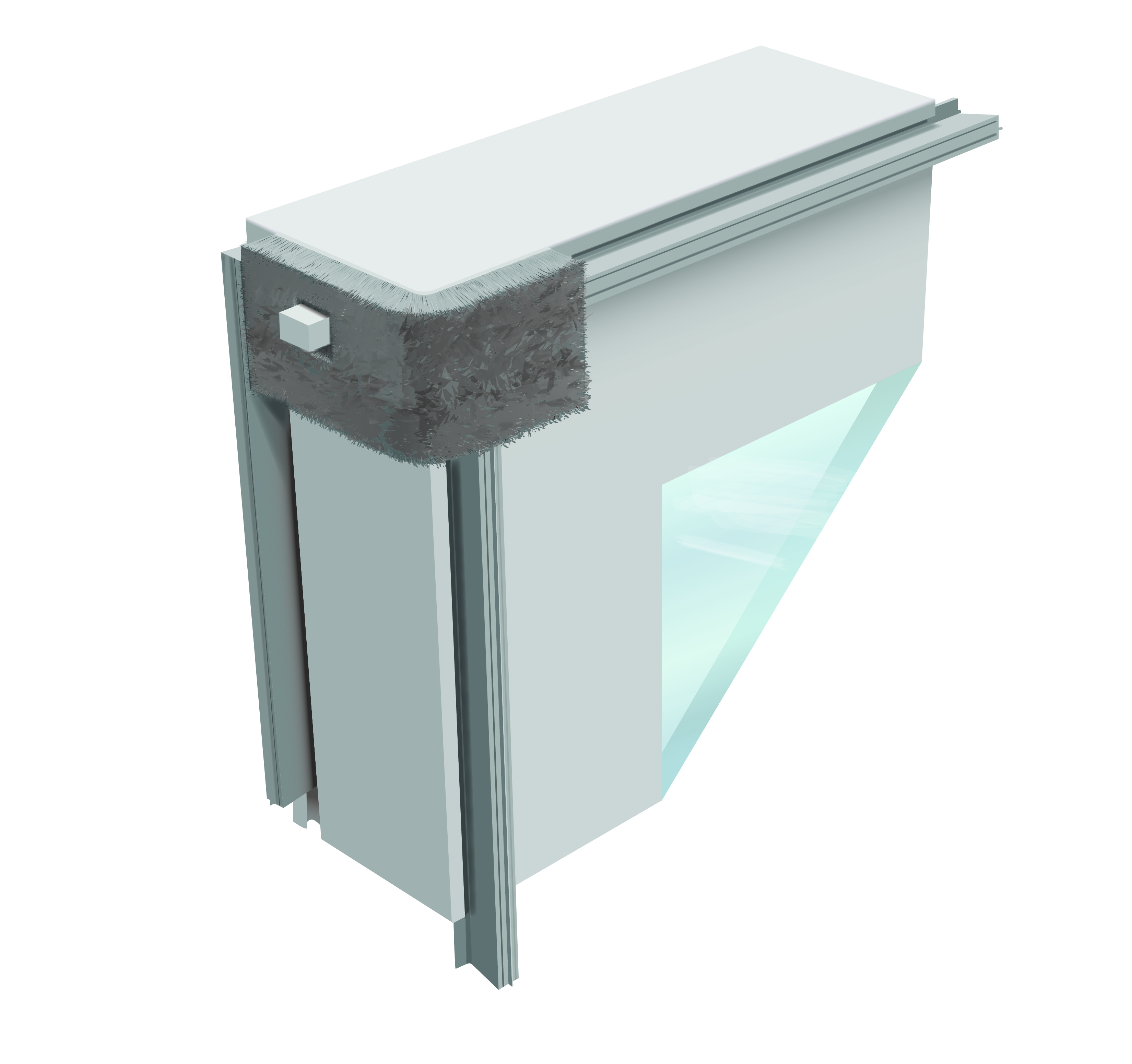

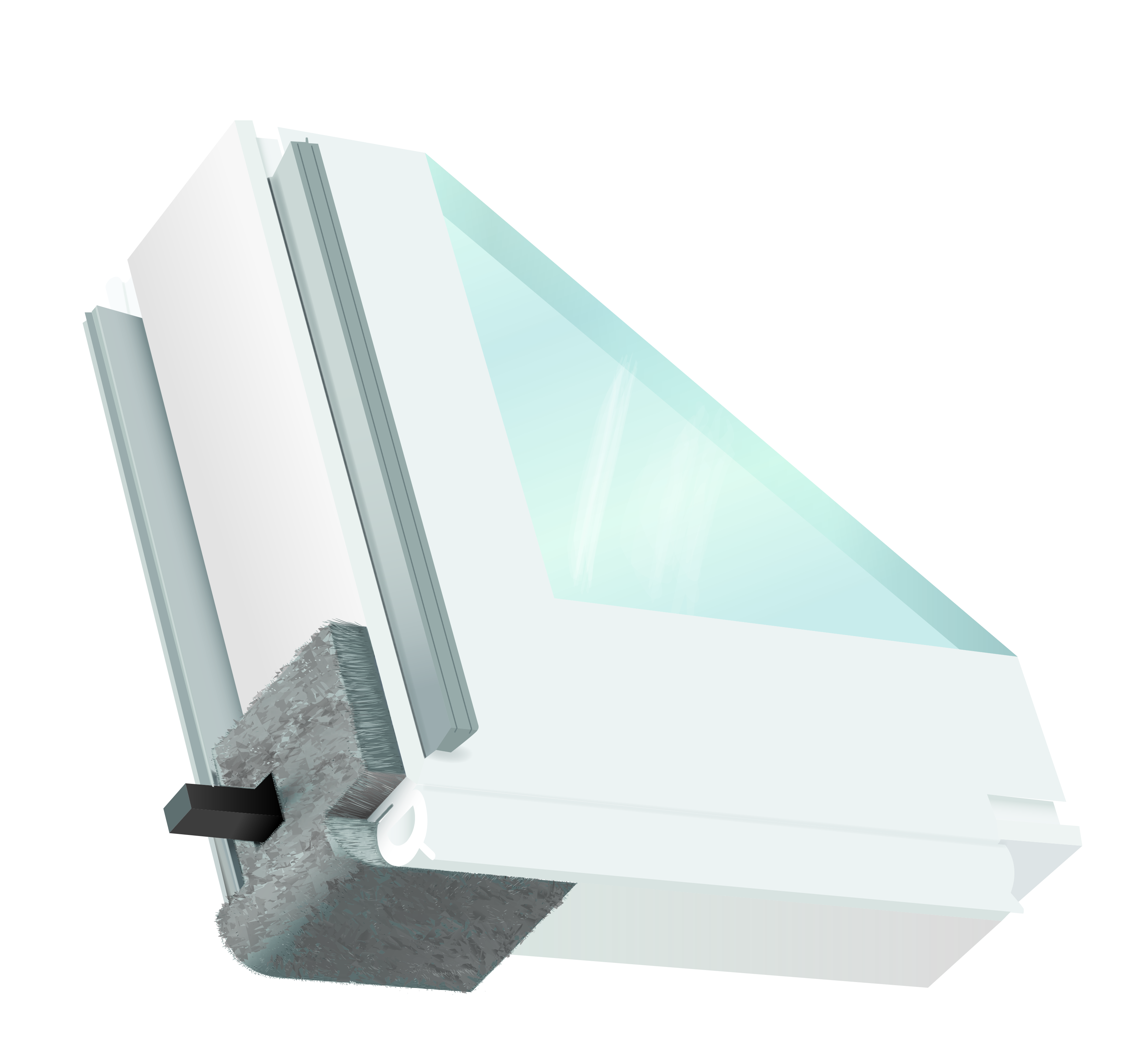

Ultrafab’s ULTRA BEND® provides superior sealing advantages to a large variety of applications including window & door, HVAC, lighting, medical imaging, and printing/kiosk. Below are some practical examples of how it can benefit specific applications.

Increase Vinyl Window Lifespan

During the sliding process, a rigid-back plug is vulnerable to getting snapped off or caught due to irregular surfaces created by heat-welded seams on vinyl windows. The ULTRA BEND® is able to flexibly adhere to these irregular surfaces. This means the dust plug is less likely to get knocked off and will provide a longer lifespan.

Reduce Spindle Friction up to 360º

Spindles, or any component that turns up to 360º, can lead to production damage without protective fibers. ULTRA BEND® is able to wrap around spindles to provide 360º of friction reduction, no matter which direction the component turns. An example of this application is an automated manufacturing process where components run down an assembly line. In order to maintain aesthetics, ULTRA BEND® can be used to prevent product surface markings as components are guided through the assembly process.

Reduce Vibration on Radius Windows

Enclosures with radius contours, such as the sliding half-moon enclosures seen on modern boats, present a unique sealing challenge due to angles that aren’t restricted to 90º. Our flex-back product can be dropped into the bottom of that channel and give the sliding window a continuous contact area throughout the internal perimeter. When used in conjunction with other seals, this reduces vibration and creates a barrier against air and water infiltration.

Sealing Advantages

- Reduces or eliminates air/water infiltration, sound/vibration, and operational force

- Fits uneven surfaces (e.g., welded corners, pockets) due to flexible base

- Fits securely and eliminates “rise” that could occur with rigid-based plugs due to flexible base combined with superior adhesive options

- Provides industry leading durability and longevity with ultrasonically welded polypropylene filament assembly

- Provides ability to wrap sealing function around perimeter, corners, radius, and other difficult to seal areas

Sealing Specs

- Pile Heights: .170″ – .600″

- Base Widths: .250″ – 1.750″

- Color Options: white, black, gray

- Material: polypropylene

- Soft touch center fin options available

- Premium PSA and Kiss Cut with Quick Release Liner

- Cut to length pieces, or lineal on a reel

- New: Custom Laser Cut Geometrics

Ready to Get Started?

Ultrafab works with OEMs and engineers to reduce cycle time and improve first time quality by designing innovative sealing components that offer a competitive advantage. If now or at any time you have questions, please contact us. During our conversation we can discuss feasibility, potential business return, and if our flexible adhesive-backed dust plug is the best fit solution for your application.

Be the First to Hear About Our Latest Innovations

Sign up for our email list